Process Development Overview

The R & D team of our company is composed of experienced scientific research experts from China and abroad. It is characterized by technological innovation and comprehensive technical ability. It has extensive and in-depth professional knowledge in the field of synthetic organic chemistry. It can independently design compound synthesis routes and has rich experience in dealing with complex compounds.

Through continuous optimization of the process to obtain mature and easy to industrialize the process route, the key process parameters database was established. According to the characteristics of the process route, complete impurity profiles of starting materials, intermediates and APIs are established, so that the prepared APIs meet the requirements of generic drug preparations, thus realizing industrial production of a certain scale.

Process development, optimization, production and writing CMC content

Synthesis process development and optimization

Synthesis process development and optimization

Optimization and determination of important process parameters

Optimization and determination of important process parameters

Optimize and determine post-processing methods

Optimize and determine post-processing methods

Optimize and determine the purification method

Optimize and determine the purification method

Process risk assessment and control (assess the hazard level of the process)

Process risk assessment and control (assess the hazard level of the process)

Process Validation and Process Transfer

Process Validation and Process Transfer

Analytical Method Development and Validation

Analytical Method Development and Validation

Trial/exploratory stability study (pre-test)

Trial/exploratory stability study (pre-test)

Separation of impurities in regulated starting materials, intermediates, APIs and drug products using various techniques such as HPLC

Separation of impurities in regulated starting materials, intermediates, APIs and drug products using various techniques such as HPLC

Identify, prepare, control and establish reasonable quality standards for impurities involved in the project

Identify, prepare, control and establish reasonable quality standards for impurities involved in the project

Rapid process development of starting materials and APIs with significant advantages in material cost control

Rapid process development of starting materials and APIs with significant advantages in material cost control

Arrangement and writing of application dossiers CMC

Arrangement and writing of application dossiers CMC

Pharmaceutical Analytical Method Development and Methodology Validation

Based on the relevant requirements of ICH and national pharmacopoeias, the development and validation of analytical methods for pharmaceutical starting materials, intermediates and APIs from R & D and production to registration application,

Analytical method development and validation for related substances/assay, including forced degradation

Analytical method development and validation for related substances/assay, including forced degradation

Development, qualification or validation of chiral methods for pharmaceuticals

Development, qualification or validation of chiral methods for pharmaceuticals

Method development, qualification or validation of residual content of impurities

Method development, qualification or validation of residual content of impurities

Development, qualification or validation of KF and CKF analytical methods for moisture

Development, qualification or validation of KF and CKF analytical methods for moisture

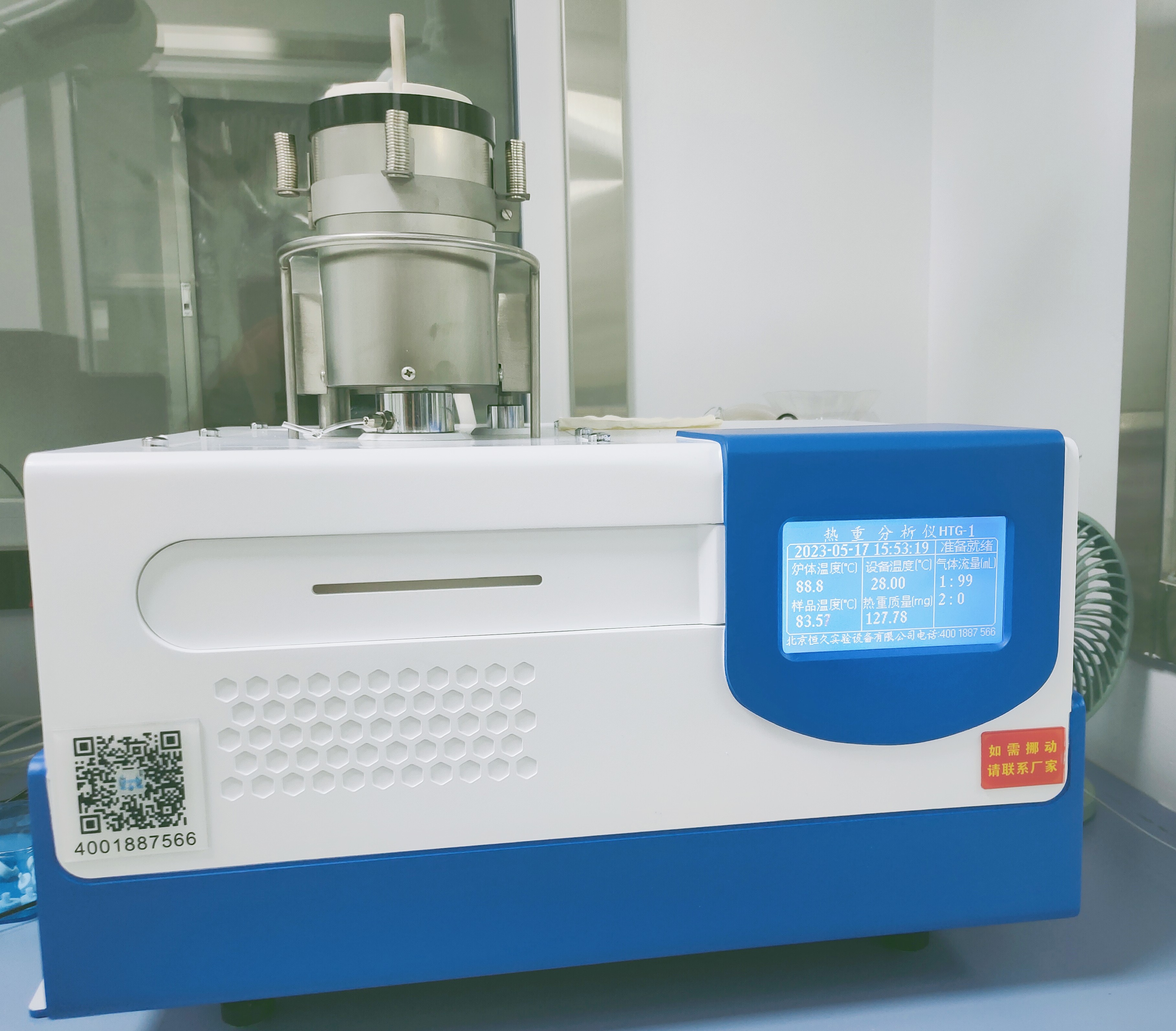

Development, qualification or validation of thermogravimetric analysis (TGA) methods

Development, qualification or validation of thermogravimetric analysis (TGA) methods

Cleaning Validation Test Method Development, Validation or Verification

Cleaning Validation Test Method Development, Validation or Verification

Compilation of Submission in CTD Format (DMF)

Compilation of Submission in CTD Format (DMF)

Drug Stability Studies

Experimental/exploratory stability study (pre-experimental) and stability study in drug registration stage

Experimental/exploratory stability study (pre-experimental) and stability study in drug registration stage

According to ICH Q1A, design corresponding stability test according to drug properties

According to ICH Q1A, design corresponding stability test according to drug properties

Stability data of analytical samples under different conditions were evaluated according to ICH Q1E

Stability data of analytical samples under different conditions were evaluated according to ICH Q1E

such as trend of data over time

such as trend of data over time

Comprehensive analysis to establish the shelf life and shelf life of samples

Comprehensive analysis to establish the shelf life and shelf life of samples

Equipped with strong light test chamber and stability test chamber

Equipped with strong light test chamber and stability test chamber

Storage conditions: 30°C/40°C/75%RH, 30 °C/65%RH, 25°C/60%RH and light

Storage conditions: 30°C/40°C/75%RH, 30 °C/65%RH, 25°C/60%RH and light

Stability study constant temperature and humidity chamber; Real-time temperature and humidity monitoring (dual system); automatic alarm system

Stability study constant temperature and humidity chamber; Real-time temperature and humidity monitoring (dual system); automatic alarm system

Compilation of Submission in CTD Format (DMF)

Compilation of Submission in CTD Format (DMF)

Drug impurity analysis

Separation of impurities in regulated starting materials, intermediates, APIs and drug products using various techniques such as HPLC

Separation of impurities in regulated starting materials, intermediates, APIs and drug products using various techniques such as HPLC

Complete 1D/2D NMR, LCMS, EA, HRMS, IR, UV data were collected to identify the structure of the separated impurities

Complete 1D/2D NMR, LCMS, EA, HRMS, IR, UV data were collected to identify the structure of the separated impurities

Isolation and structure identification of forced oxidation degradation products

Isolation and structure identification of forced oxidation degradation products

Compilation of Submission in CTD Format (DMF)

Compilation of Submission in CTD Format (DMF)